New York Air Brake Company

- Guaranteed authentic document

- Orders over $75 ship FREE to U. S. addresses

Product Details

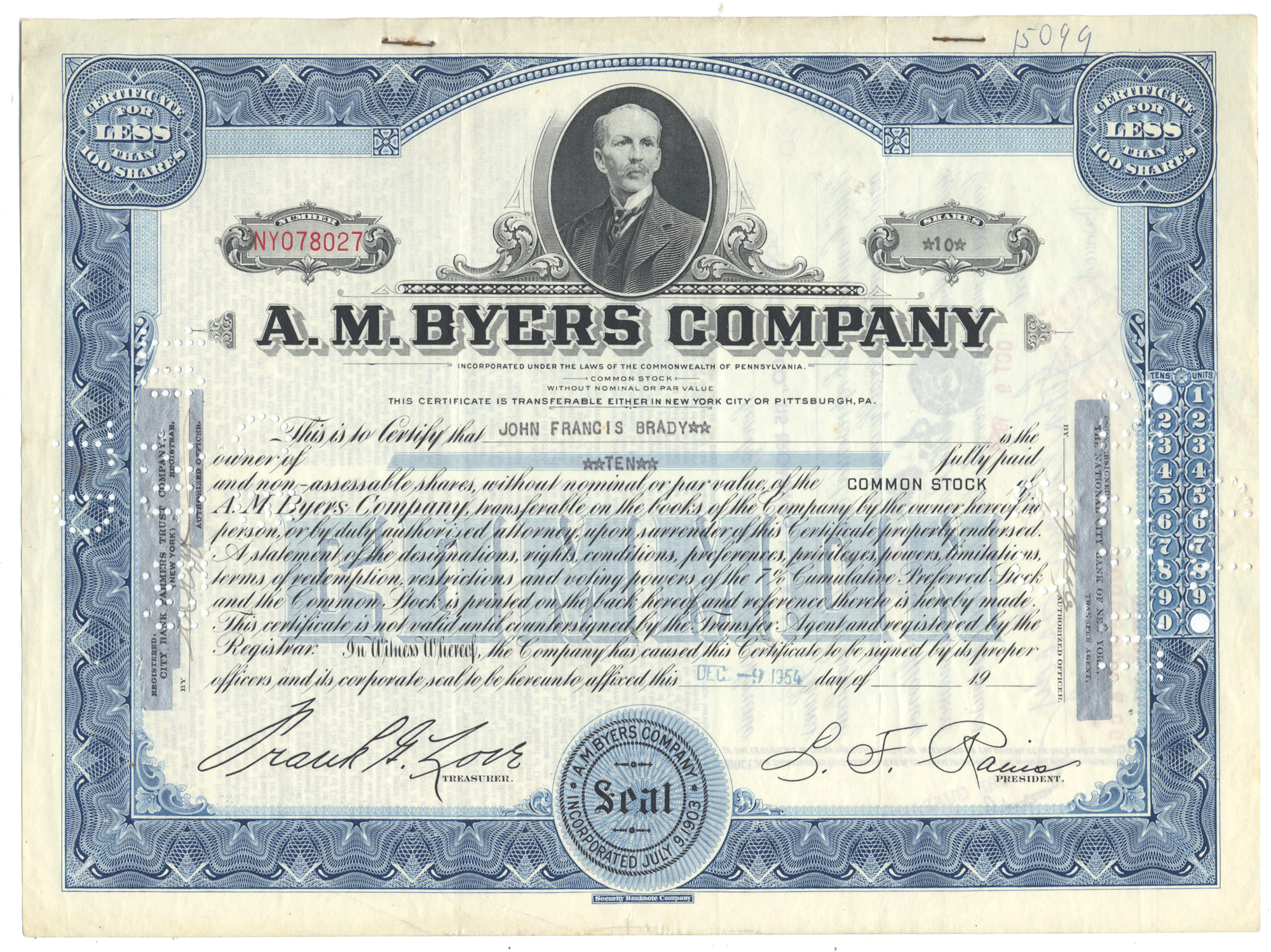

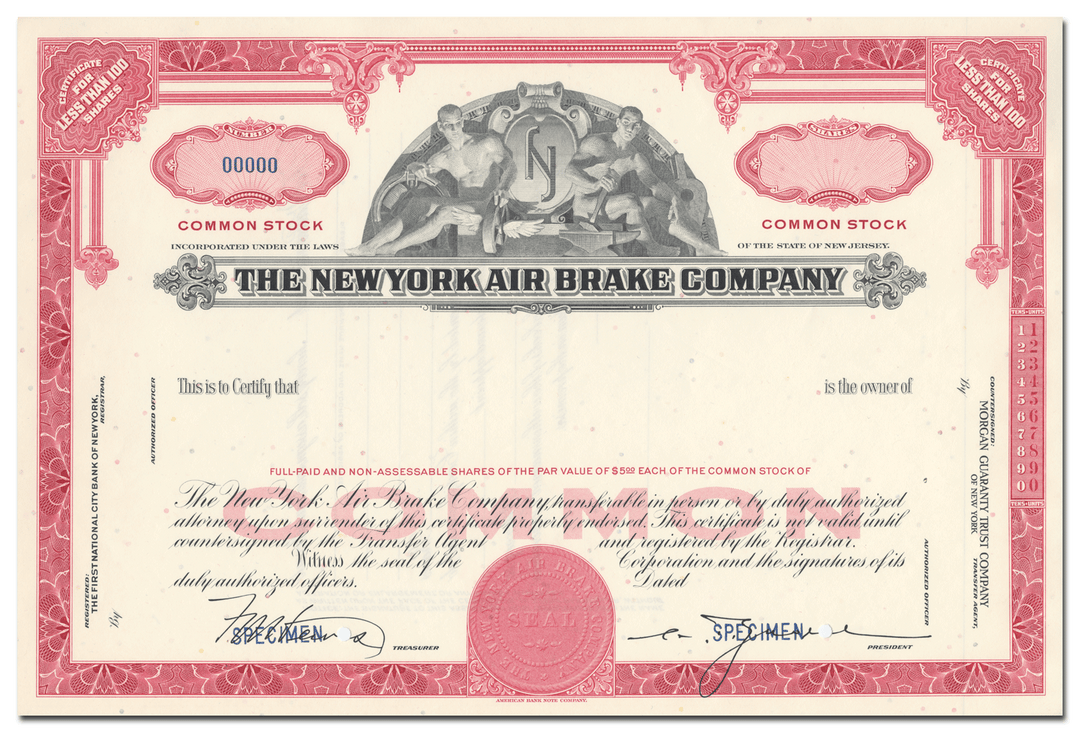

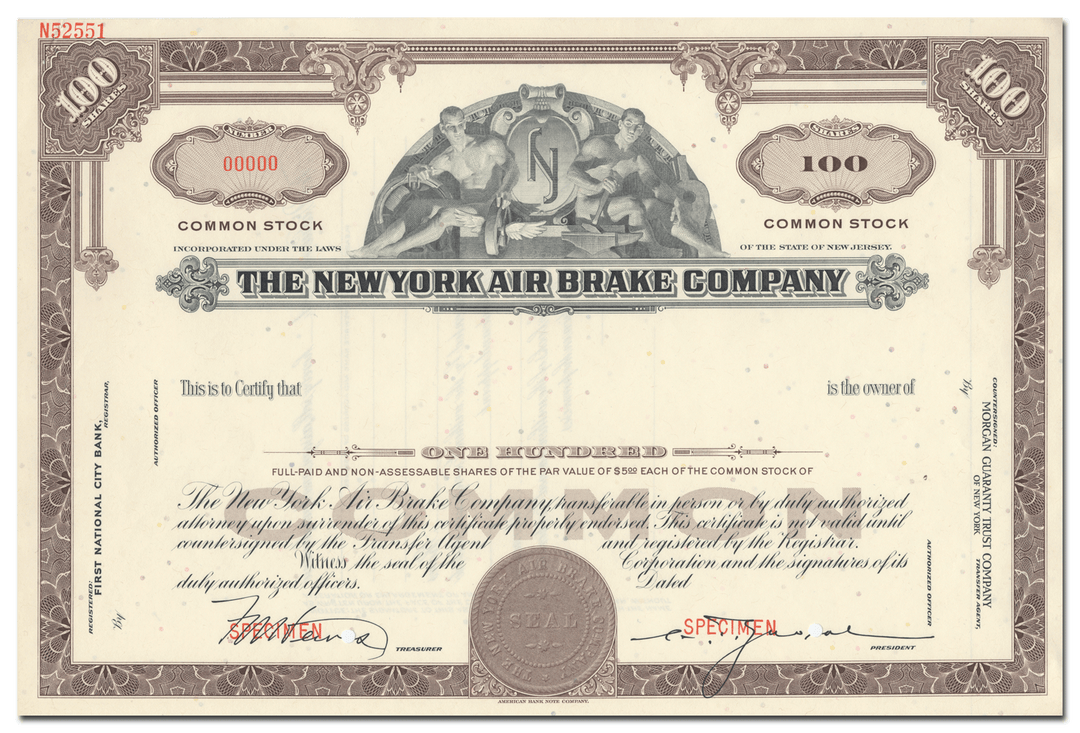

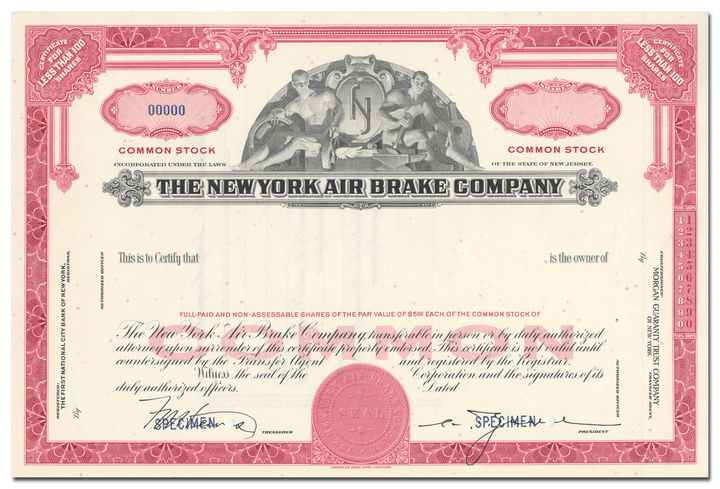

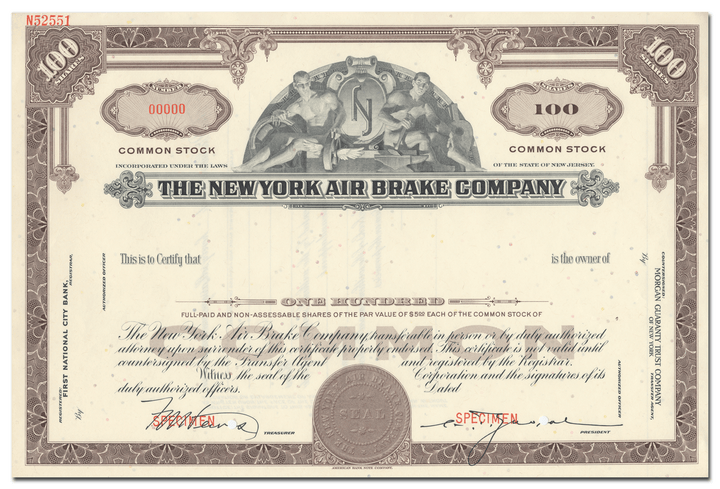

| Company | New York Air Brake Company |

| Certificate Type | Common Stock |

| Date Issued | Specimen, circa mid 1900's |

| Canceled | Yes |

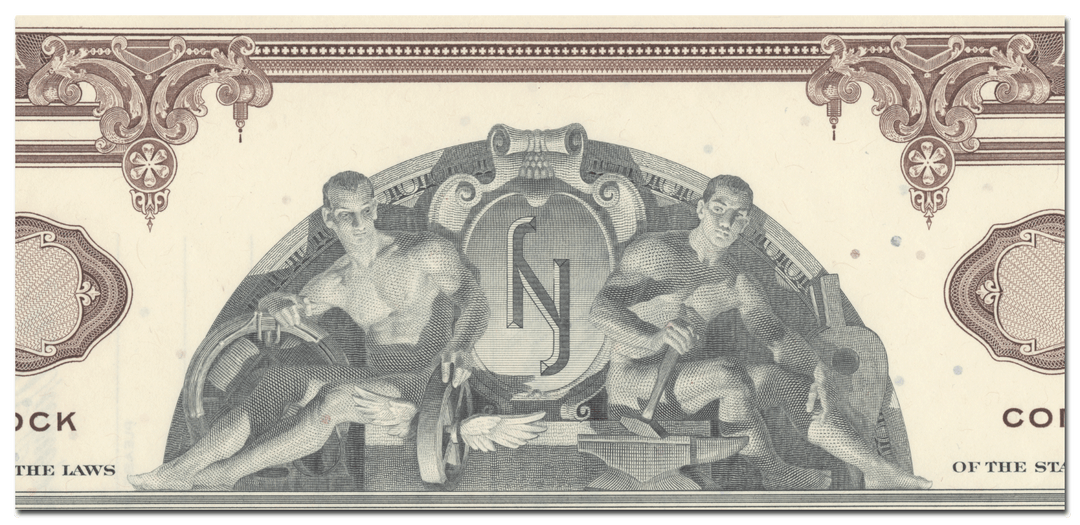

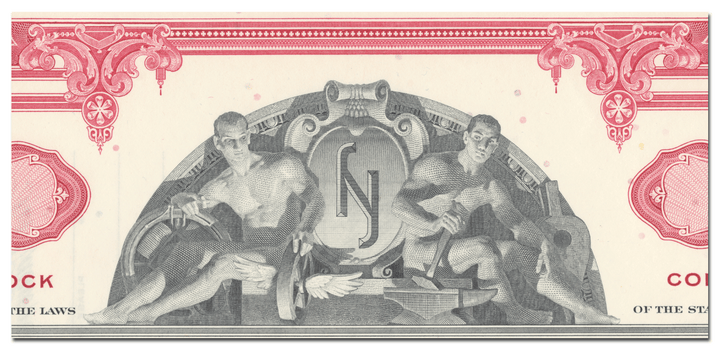

| Printer | American Bank Note Company |

| Signatures | Machine printed |

| Approximate Size |

12 1/2" (w) by 8" (h) |

|

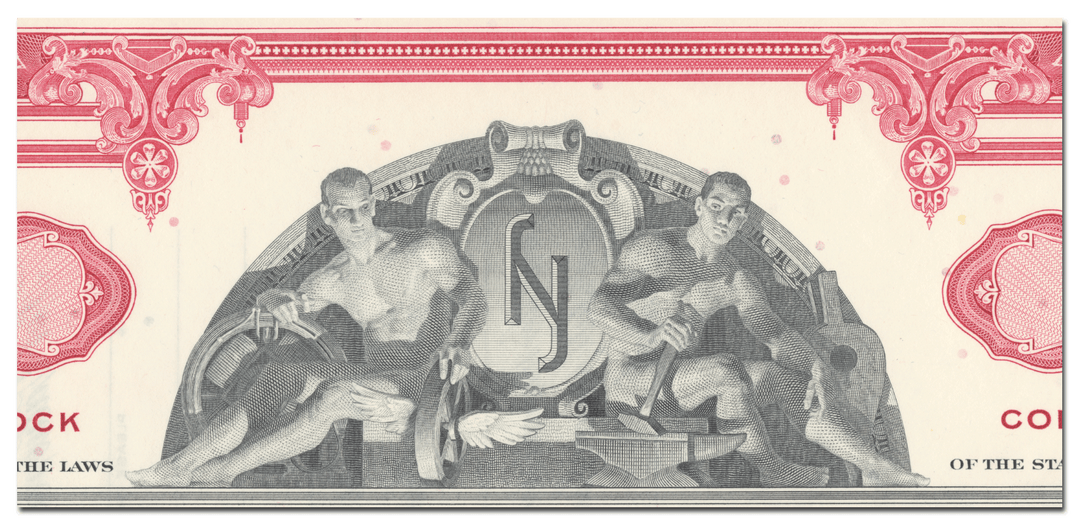

Product Images |

Representative of the piece you will receive |

| Authentic | Yes |

| Additional Details | NA |

Historical Context

New York Air Brake was established on July 1, 1890 acquiring all of the property and business of Eames Vacuum Brake Company. Eames Vacuume Brake Company had previously been in existence since 1876 manufacturing vacuum brakes. The new company erected ten new buildings on Beebee Island and nearby shores just in time for a booming brake market driven by an 1893 law mandating standardized brakes for all railroad cars.

In 1902, NYAB bought the 268-acre Poole Farm in Watertown, New York, and began its move to its present location. The new works were planned as a model industrial enterprise, providing housing, work, and recreation for 1,000 employees on the grounds. The workers, however, decided that they did not want to live next door to their workplace and the plan was scrapped. In 1903, the new foundry became the first part of the new plant to begin operations.

During this period NYAB's main competition was Westinghouse Air Brake Company, which lead the market in locomotive braking sales. Despite Westinghouse's lead, American railroads preferred to have two brake suppliers. James Hill, builder of the Great Northern Railway, and the New York Central Railroad were especially supportive of New York Air Brake's technology. In 1912, NYAB and Westinghouse agreed to share the market, along with research and development. NYAB's 25 percent share of the brake market soared to $3 million per year by 1914.

In 1915, NYAB shifted focus of their current manufacturing of vacuum brakes to efforts toward the First World War. Sales grew from $4.7 million in 1915 to $24 million in 1916. By 1918, the company employed 7,000 who were involved in defense manufacturing, including the production of horse-drawn cannons.

After World War I, it was decided that a new braking system needed to be developed to provide braking power for the ever growing freight train industry. Engineers at New York Air Brake contributed to the development of what came to be known as the "AB" brake. During the mid-1930s, at the same time the "AB" brake was being widely implemented, the pneumatic and electro-pneumatic braking equipment for modern, high-speed locomotives and passenger trains were engineered and produced at the Watertown facilities.

A dramatic drop in sales following the end of World War I led New York Air Brake to seek new markets. In 1919, the company built and marketed a "Three-Point Truck;" an "enormous affair, the four wheels alone weighing nearly one ton. The truck had a 15-foot wheelbase, and an overall length of 19 feet. It weighed about 8,100 pounds and had a carrying capacity of from three to six tons..." It was not a success.

In 1925, new management announced another try at the auto industry with the introduction of the Gerlinger hydraulic lumber carrier; an engine, and a cab set high atop a lumber rack. The project faded quickly.

Westinghouse and New York Air Brake began development of a replacement for the venerable "K Brake" in 1929. The Great Depression slowed, but did not stop, development of the new brake and, in April 1932, New York Air Brake began construction of a 200-car test track, the largest in the world. In 1934, the Association of American Railroads (AAR) voted to adopt the new composite AB brake. Despite the Depression, the company maintained employment for 300 workers, many on a part-time basis.

In 1945, New York Air Brake again returned to aiding the United States' war effort in World War II. Up until the end of the war, NYAB became a producer of tank hulls for the Sherman tank, anti-aircraft shells, automatic pilots for aircraft, breech mechanisms for guns, hydraulic pumps for fighter aircraft, and other military hardware and had over 5,000 employees contributing to the war effort in the war-torn Europe by the end of 1944.

By the end of the Second World War, New York Air Brake had expanded its product line to include hydraulic aircraft pumps. In 1949, the company furthered its market reach with the purchase of the Hydraulic Equipment Company and the Dudco Products Company. As a result, sales leapt from $18 million in 1950 to more than $45 million in 1957.

On June 15, 1967, NYAB merged with General Signal Corporation.

Related Collections

Additional Information

Certificates carry no value on any of today's financial indexes and no transfer of ownership is implied. All items offered are collectible in nature only. So, you can frame them, but you can't cash them in!

All of our pieces are original - we do not sell reproductions. If you ever find out that one of our pieces is not authentic, you may return it for a full refund of the purchase price and any associated shipping charges.